The tobacco products industry (IHT) is one of the sectors that contributes greatly to the national economy in Indonesia. One of the IHT products is cigarettes. One cigarette butt contains various dangerous substances such as arsenic, pyridine, and heavy metals, which, if thrown away, can pollute water. Liquid waste produced by IHT also contains nicotine, nitrosamines, and heavy metals such as Cu (copper) and Pb (lead), which can pollute waters and contaminate drinking water sources. According to the WHO, the habit of throwing cigarette butts carelessly is carried out by millions of people; at least two-thirds of cigarette butts are found scattered on sidewalks, cafes, and parks and end up in rivers and even the ocean.

The tobacco products industry (IHT) is one of the sectors that contributes greatly to the national economy in Indonesia. One of the IHT products is cigarettes. One cigarette butt contains various dangerous substances such as arsenic, pyridine, and heavy metals, which, if thrown away, can pollute water. Liquid waste produced by IHT also contains nicotine, nitrosamines, and heavy metals such as Cu (copper) and Pb (lead), which can pollute waters and contaminate drinking water sources. According to the WHO, the habit of throwing cigarette butts carelessly is carried out by millions of people; at least two-thirds of cigarette butts are found scattered on sidewalks, cafes, and parks and end up in rivers and even the ocean.

CIGAMONS is here as the Jember University PKM-RE Team to answer this problem. The team consists of 5 people, namely Moh. Zeinur Ridho, Retno Pertiwi, Eldo Delta Bagaskara, Raya Rambu Rambani from S1 Chemistry, and Chika Synthia Pitaloka from S1 Environmental Engineering who were supervised by Dr. Muhammad Reza, S.Si., M.Sc., M.Si. This team successfully passed funding for the Student Creativity Program in the field of Exact Research (PKM-RE), with the title “Pemanfaatan Puntung Rokok Bekas Termodifikasi Surfaktan Alami Sebagai Adsorben Timbal Pada Limbah Cair Industri Rokok Dalam Upaya Penerapan Ekonomi Sirkular“. Adsorbents can help overcome the above problems by absorbing heavy metals which are one of the dangerous contents in waste. Adsorbents are created specifically for Pb (Lead) so that this content can be removed and can help neutralize the dangers of waste.

The research was carried out in several stages including sample preparation, carbonation, adsorbent synthesis with modification of natural surfactants, characterization and adsorption tests. The material used is used cigarette butts which are then prepared by separating the filter from the skin and then soaking it with distilled water, ethanol, acetic acid and nitric acid to remove contaminants and dangerous substances. The butts are then dried in the sun and after drying they proceed to the carbonation process.

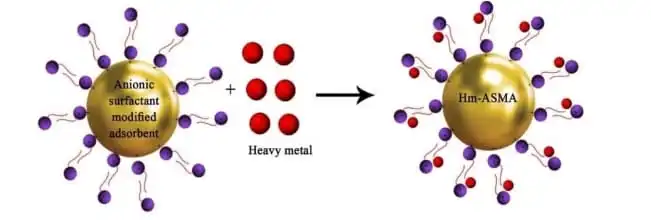

The resulting carbon is activated with KOH, then filtered to obtain pure activated carbon separated from the filtrate, accompanied by pH neutralization using HCl and distilled water. The activated carbon is then dried in an oven to remove any remaining liquid content or residual solution, then ground with a grinder to reduce the particle size so that the surface area becomes larger. The activated carbon is then sieved to obtain a uniform particle size, namely in the range 0-50 mesh, and then modified with a natural surfactant, namely DCG (Disodium Cocoil Glutamate) solution.

DCG modified activated carbon is produced after the same stages when activated with KOH, namely going through a filtration and oven drying process as well. The DCG modified activated carbon was then characterized using FTIR (Fourier Transform Infra Red) whose aim was to determine the functional groups in the sample that contributed new characters after modification. Finally, the adsorption test was carried out using a Pb solution on an incubator shaker.

What is very interesting about this adsorbent is that apart from being able to solve environmental problems by adsorbing heavy metals such as lead, its adsorption capacity is very good and effective compared to ordinary adsorbents because it has been modified with a natural surfactant, namely DCG. Apart from that, the circular economy concept is also applied here, namely solving the problem of cigarette waste by using used cigarette butts. Very cool huh!!! Complete information and various matters related to CIGAMONS can be accessed on the related social media:

Instagram (@cigamons_pkmre)

Tiktok (@cigamons_pkmre)